How to Select the Right Hybrid Stepper Motor for Your Automated Packaging Line: A Comprehensive Technical Guide

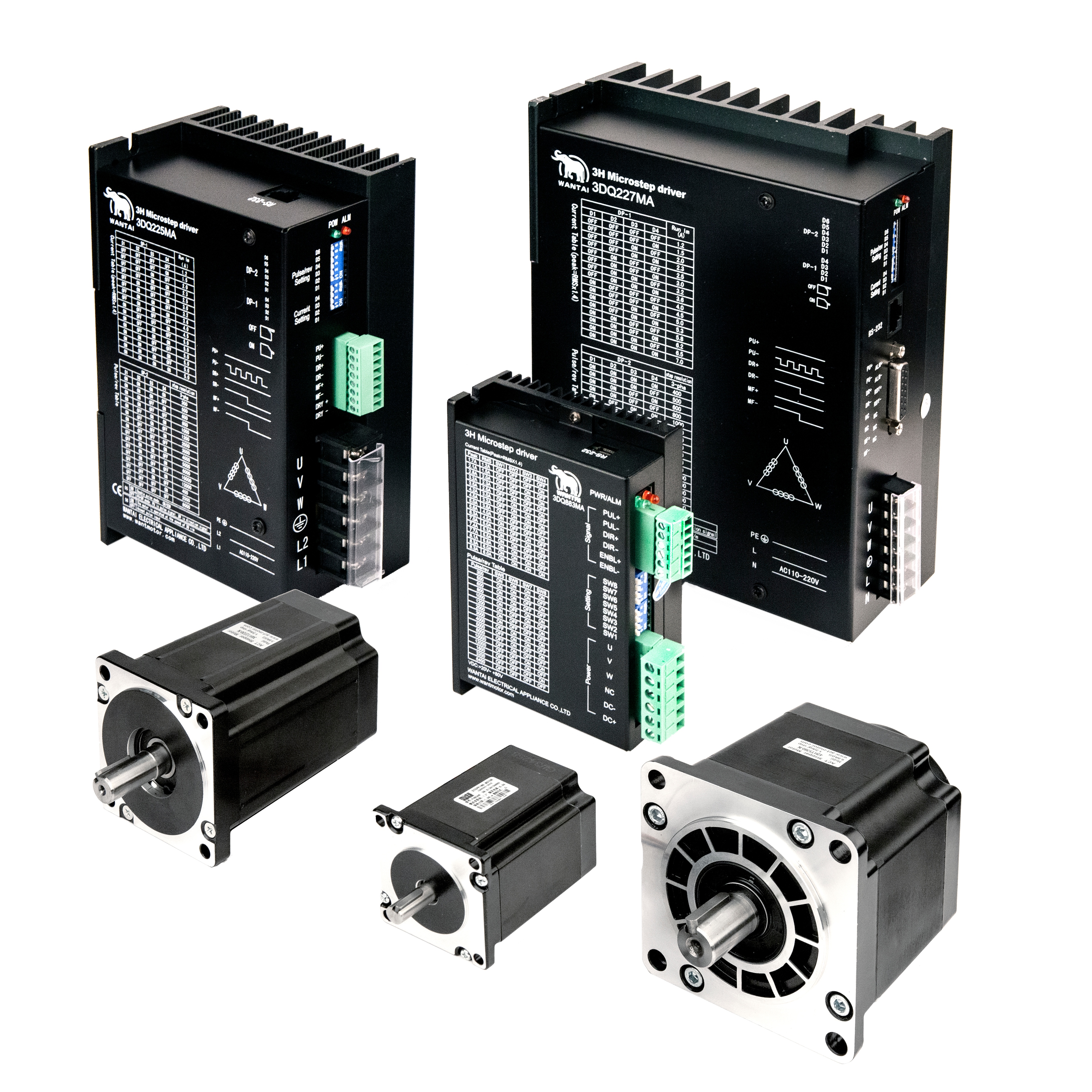

As global e-commerce and consumer goods demand continues to surge, automated packaging lines are under immense pressure to deliver higher speed, greater precision, and unwavering reliability. At the heart of many of these systems lies the Hybrid Stepper Motor. Selecting the correct motor is not just a procurement decision; it's a critical engineering choice that impacts throughput, product quality, and total cost of ownership. This guide, leveraging insights from industry leader ACT MOTOR, will walk you through the key technical and practical considerations for choosing the optimal High-torque stepper motor for automated packaging lines.

Step 1: Define Your Core Motion Requirements

Before diving into catalogs, clearly define what the motor needs to do. This forms the basis of all subsequent choices.

- Load & Torque: Calculate the peak and continuous torque required. For packaging lines, this includes the inertia of belts, pulleys, product weight, and friction. High-torque stepper motors from ACT MOTOR, like their NEMA 34 frame models, are often specified for heavy-duty carton sealing or palletizing stations.

- Speed & Acceleration: Determine the required operational RPM and how quickly the motor must reach that speed. High-speed filling or labeling stations may prioritize different characteristics than intermittent motion for case packing.

- Accuracy & Repeatability: Define the positional accuracy needed. For precise cut-off or placement operations, a High-Precision Hybrid Stepper Motor or a stepper motor with encoder for closed-loop feedback might be necessary.

- Duty Cycle: Will the motor run continuously, or in start-stop cycles? This affects thermal management and motor sizing.

Step 2: Choose the Motor Type & Configuration

Not all hybrid stepper motors are created equal. Match the motor type to your mechanical design.

Standard Hybrid Stepper Motors

Ideal for direct drive or simple belt systems. ACT MOTOR offers a wide range, including 8HS Hybrid Stepper Motors for compact spaces and NEMA8 Hybrid Stepper Motors for light-duty applications.

Geared & Lead Screw Stepper Motors

For applications requiring higher torque at lower speeds or converting rotary to linear motion.

- Geared Stepper Motors (Gearbox stepper motor): Provide increased torque and reduced reflected inertia. Perfect for controlled indexing of heavy loads.

- Lead Screw Stepper Motors & Ball Screw Stepper Motors: Integrate a linear actuator. Excellent for vertical lifting in packaging or precise linear positioning. ACT MOTOR's integrated stepper motors simplify design and assembly.

Specialized Motors for Enhanced Functionality

Brake Stepper Motors: Essential for vertical axes to prevent dropping loads during power loss. Closed-loop stepper motors combine the simplicity of steppers with the error-correction of servos, ideal for closed-loop stepper motors for industrial robots on the packaging line or high-reliability stations.

Step 3: Select the Appropriate Driver & Control System

The Stepper Motor Drivers are as crucial as the motor itself. They determine performance, smoothness, and efficiency.

- Microstepping Drivers: Provide smoother motion and higher effective resolution, reducing vibration and noise—key for high-speed packaging.

- Current Rating: The driver's current output must match or exceed the motor's phase current. Under-driving reduces torque; over-driving causes overheating.

- Communication Interface: Ensure compatibility with your PLC or controller (e.g., Pulse/Dir, CANopen, Ethernet).

- Intelligent Features: Modern drivers from suppliers like ACT MOTOR offer features like current reduction at standstill (to reduce heat) and resonance suppression, which are vital for Intelligent Load-Adaptive Hybrid Stepper Motor systems.

Step 4: Consider Environmental & Compliance Factors

Packaging environments can be harsh. Your motor selection must account for this.

- Ingress Protection (IP Rating): For washdown areas (e.g., food packaging) or dusty environments, specify motors with suitable IP ratings.

- Temperature: Motors generate heat. Ensure the selected motor's thermal characteristics align with ambient conditions and duty cycle.

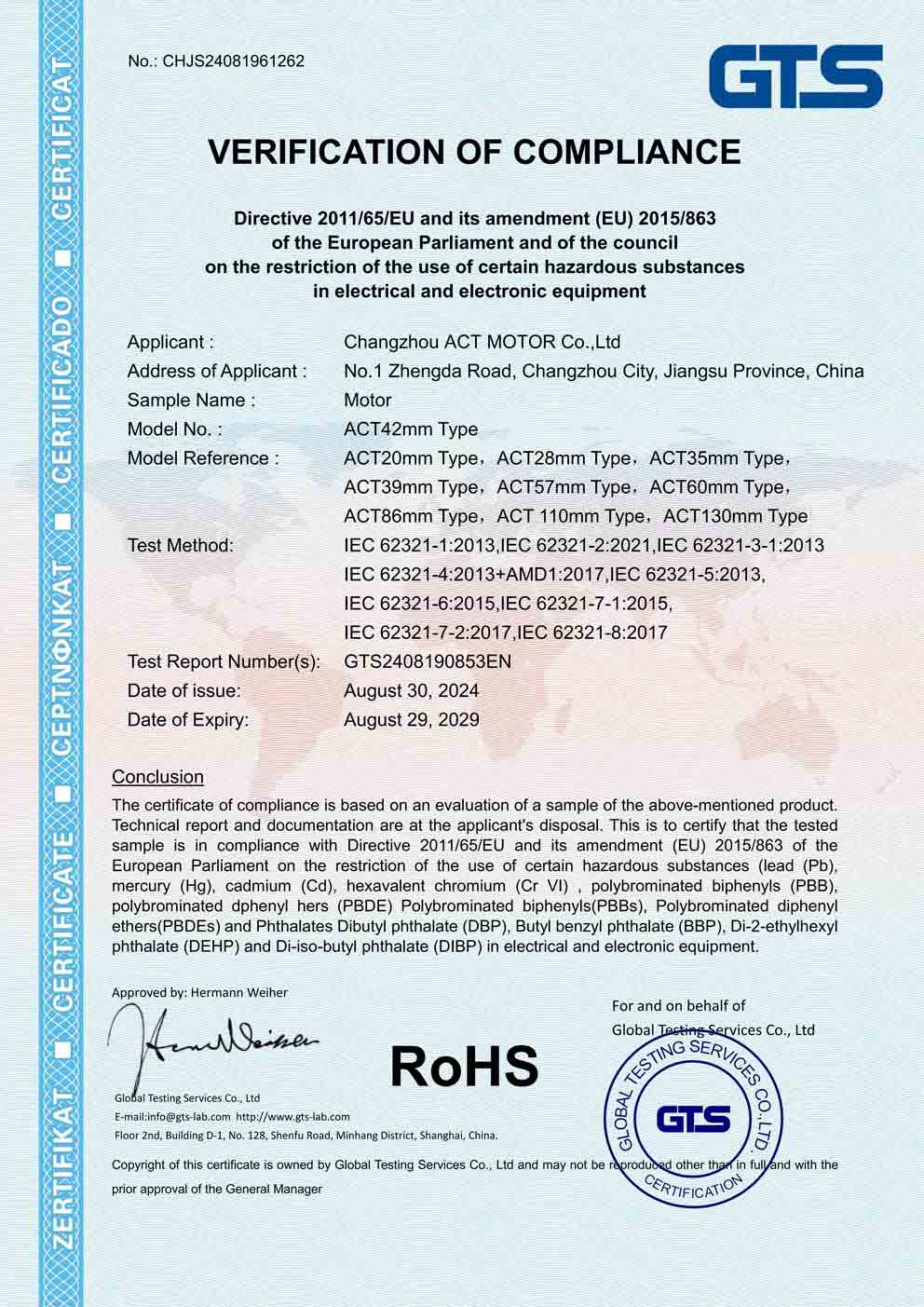

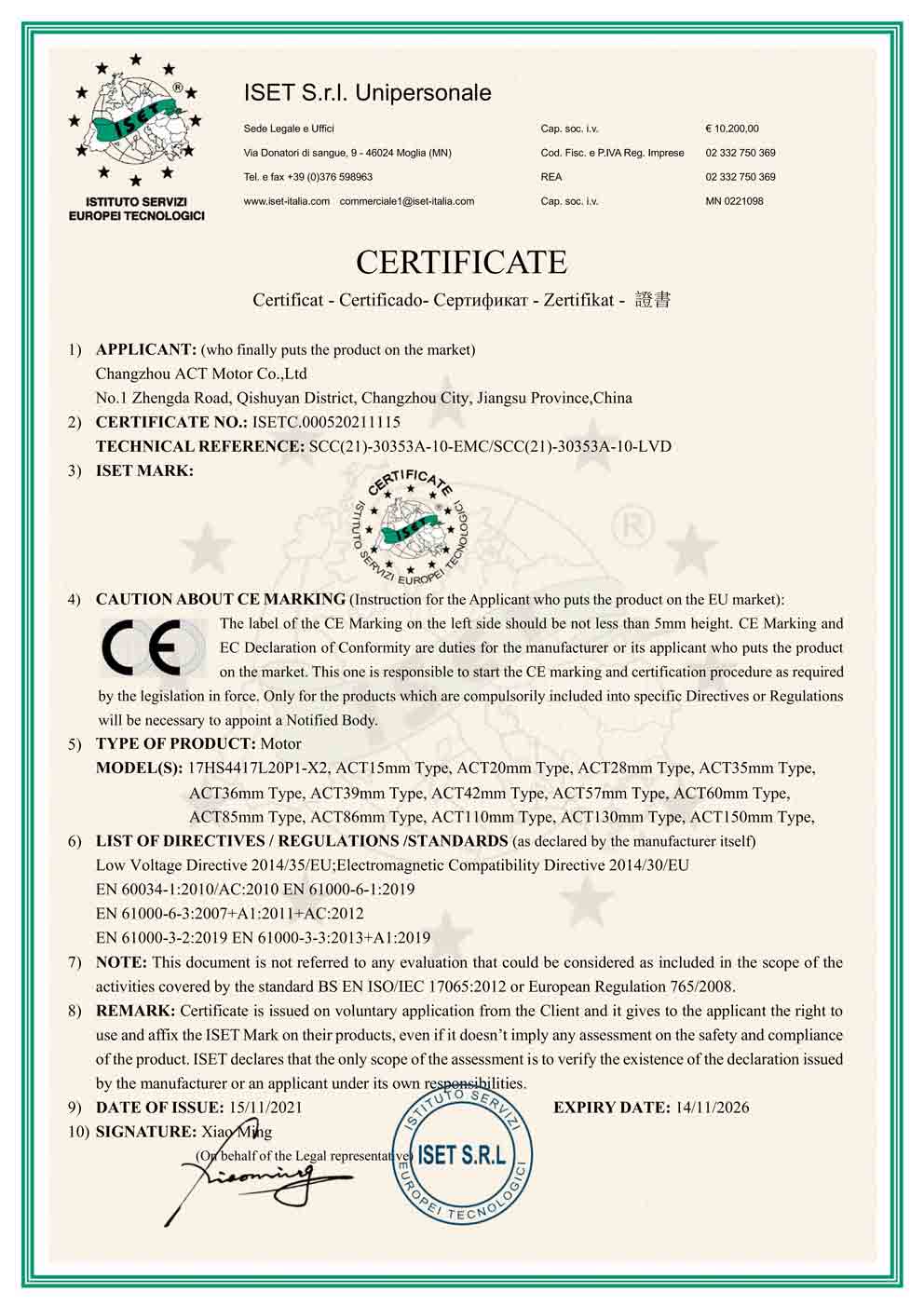

- Certifications are Non-Negotiable: For global markets and responsible manufacturing, insist on certified products. Changzhou ACT Motor Co., Ltd. demonstrates its commitment through ROHS-Compliant Stepper Motors and IS09001 Stepper Motors production systems. Always verify certificates like CE for the European market.

Step 5: Evaluate the Supplier's Capability & Support

The best technical specs are undermined by poor supply chain support.

- Technical Expertise: Can the supplier, like ACT MOTOR with its R&D focus, provide application engineering support? Their experience with stepper motors for textile machinery and stepper motors for syringe pumps translates to understanding complex motion profiles.

- Manufacturing Scale & Quality: ACT MOTOR's 70,000 square meters of modernized production facilities ensure consistent quality and the ability to scale with your demand. A visit to their website www.act-motor.com showcases their infrastructure.

- Global Service Network: With a branch in Bremen, Germany, and offices in Shanghai and Jinan, ACT MOTOR exemplifies the local support needed for timely technical service and spare parts.

- Total Cost of Ownership (TCO): Look beyond the unit price. Consider energy efficiency (linked to driver technology), reliability (minimizing downtime), and longevity. A high-quality, certified motor often has a lower TCO.

Conclusion: Partnering for Packaging Line Excellence

Selecting the right Hybrid Stepper Motor is a multi-faceted process balancing torque, speed, precision, environment, and supplier reliability. By following this structured approach—from defining requirements to vetting supplier credentials—you can specify a motion solution that maximizes your packaging line's performance and uptime.

For engineers designing the next generation of automated packaging, logistics sorters, or medical devices, partnering with an innovative and certified manufacturer is key. ACT MOTOR, with its comprehensive portfolio from standard NEMA8 Hybrid Stepper Motors to advanced Intelligent Load-Adaptive and closed-loop systems, provides the core power and technical partnership needed to drive automation forward.

Ready to specify your motor? Contact ACT MOTOR's engineering team for a consultation:

📞 Phone/WhatsApp: +86 13961261588

📧 Email: market@act-motor.com

🌐 Website: www.act-motor.com

🏢 Address: No.18, Boyang Road, Jintan Area, Changzhou, Jiangsu, China