The Ultimate Buyer's Guide to Stepper Motors with Encoders in 2026

As we move deeper into 2026, the push for smarter, more precise, and more reliable factory automation has never been stronger. A key component driving this evolution is the stepper motor with encoder, a technology that bridges the gap between traditional open-loop control and the high cost of full servo systems. For engineers, procurement managers, and system integrators, selecting the right Hybrid Stepper Motor with an encoder is a critical decision that impacts machine performance, uptime, and total cost of ownership. This comprehensive buyer's guide will walk you through the essential factors, technical considerations, and industry trends to help you make an informed choice for your next automation project.

Why a Stepper Motor with Encoder? Understanding the Core Value

Traditional stepper motors operate in an open-loop system. While cost-effective, they can suffer from missed steps under high load or sudden changes, leading to positional errors. A closed-loop stepper motor system, which integrates an encoder, continuously monitors the motor's actual position and provides feedback to the driver. This simple addition transforms the system, offering several compelling advantages:

- Elimination of Lost Steps: The encoder detects any position deviation and commands the driver to correct it immediately, ensuring absolute positional accuracy.

- Increased Throughput and Efficiency: With the safety net of feedback, systems can often be run at higher speeds without the risk of stalling, boosting overall equipment effectiveness (OEE).

- Enhanced System Diagnostics: Real-time feedback allows for monitoring of torque, vibration, and system health, enabling predictive maintenance.

- Optimal for Demanding Applications: This makes them ideal for closed-loop stepper motors for industrial robots, High-Precision Hybrid Stepper Motor needs in medical devices, and stepper motors for syringe pumps where accuracy is non-negotiable.

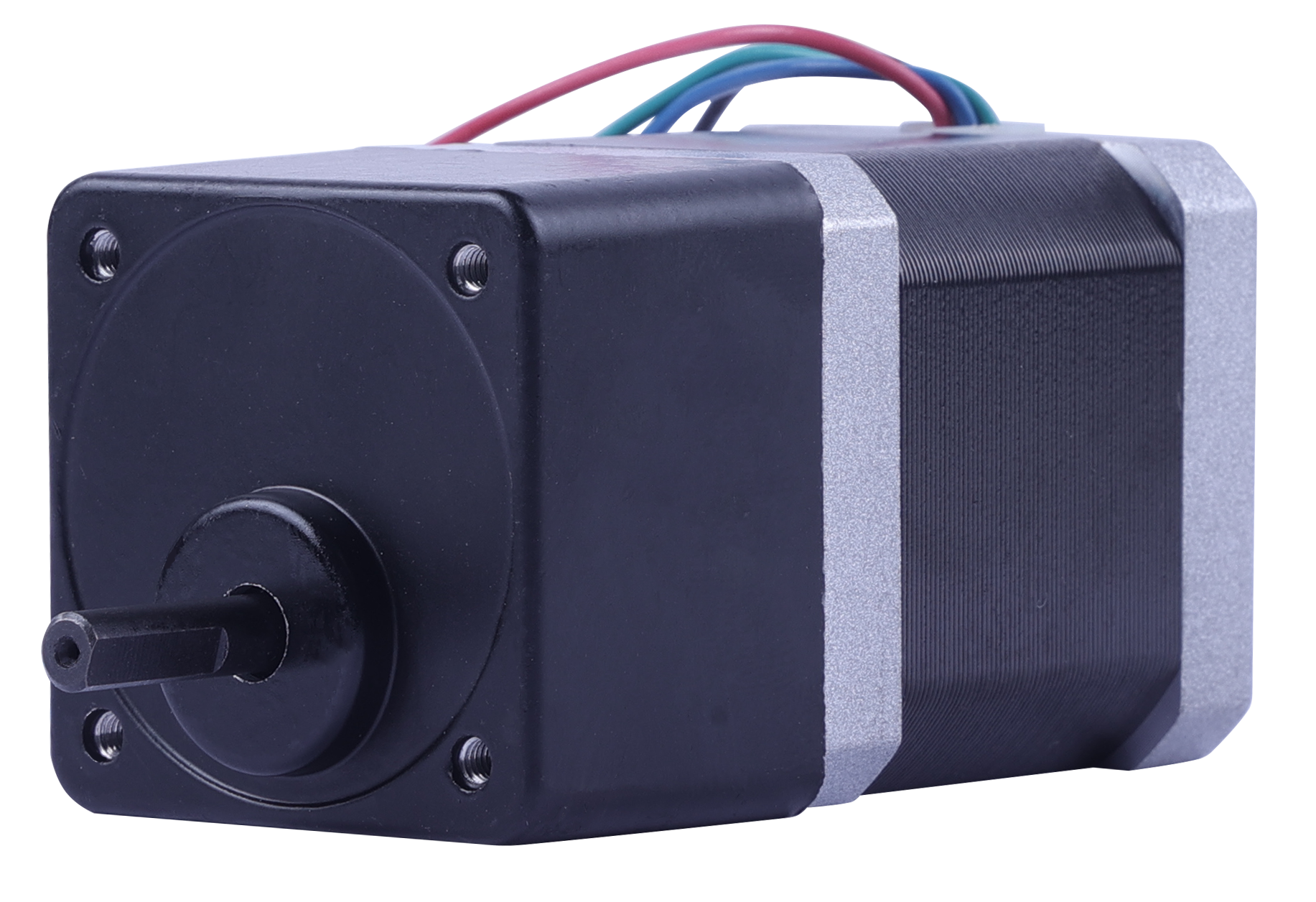

Figure: A high-performance closed-loop stepper motor system, combining a hybrid motor with a compact encoder for real-time feedback.

Key Selection Criteria for Your Hybrid Stepper Motor with Encoder

Navigating the specifications can be daunting. Focus on these critical parameters to narrow down your search:

1. Encoder Type and Resolution

The encoder is the heart of the feedback system. Common types include incremental optical encoders and magnetic encoders. Resolution, measured in pulses per revolution (PPR), determines the system's positioning granularity. For High-Precision Hybrid Stepper Motor applications in laser cutting or semiconductor handling, a higher resolution (e.g., 2500 PPR or more) is crucial. For general automation like a Logistics Sorter Pushing Hybrid Stepper Motor, a standard 1000 PPR encoder may suffice.

2. Motor Frame Size and Torque

Match the motor's physical size (NEMA 17, 23, 34, etc.) and torque output to your mechanical load and space constraints. Remember that adding a gearbox stepper motor can significantly increase output torque at the expense of speed. For applications requiring both high force and precision, such as ball screw stepper motors in vertical lifts, ensure the motor's holding and dynamic torque ratings exceed your calculated requirements by a safe margin (15-20%).

3. Driver Compatibility and Communication

The stepper motor with encoder must be paired with a compatible closed-loop driver. Ensure the driver supports the encoder's signal type (A/B/Z channels). Modern Stepper Motor Drivers offer advanced communication protocols like EtherCAT, CANopen, or Modbus TCP, which are essential for integrated stepper motors within Industry 4.0 networks. Verify the driver's current and voltage ratings match the motor.

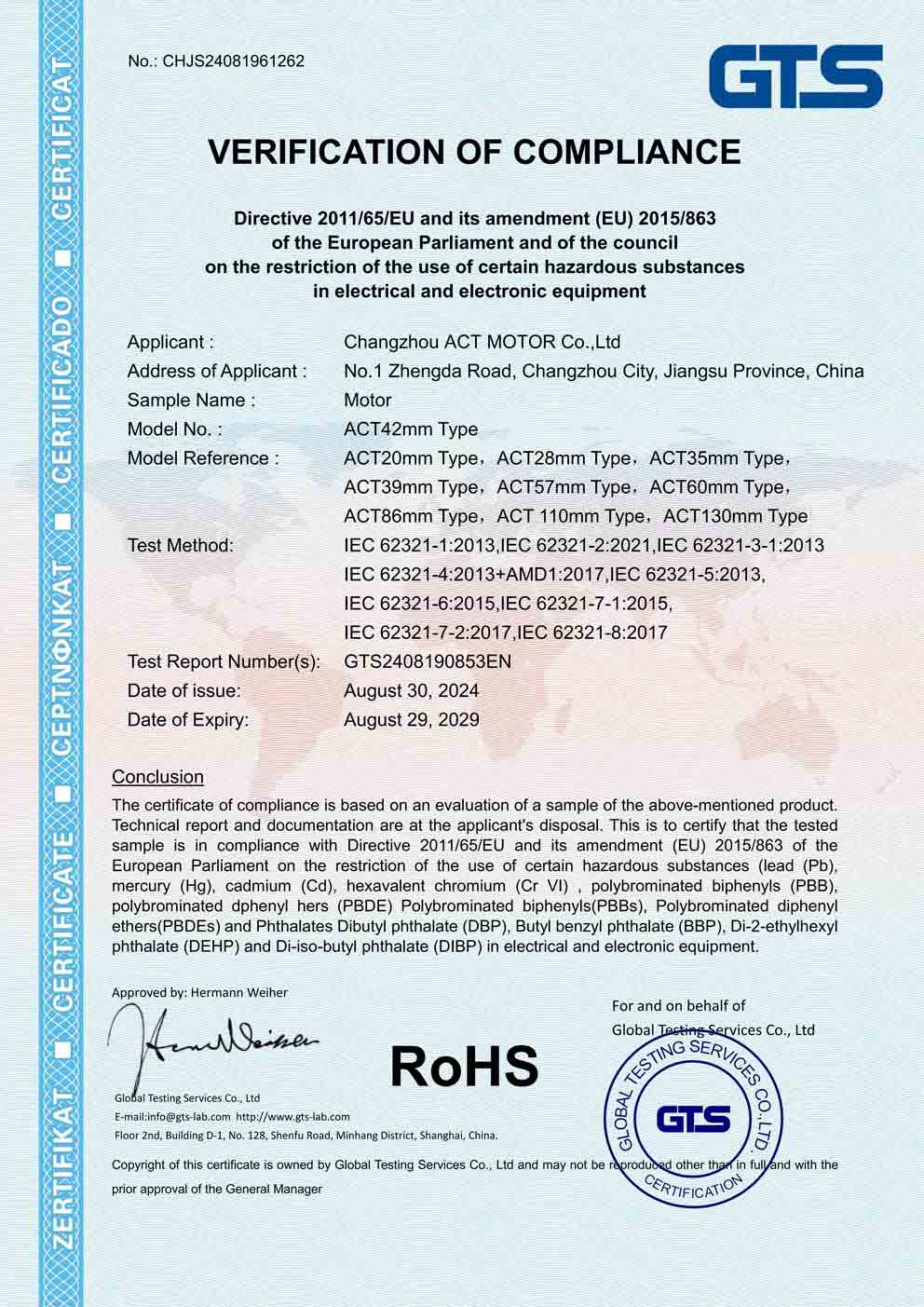

4. Environmental and Compliance Requirements

Industrial environments can be harsh. Look for motors with appropriate IP ratings for dust and moisture protection. Compliance with international standards is a mark of quality and safety. Always prioritize suppliers whose products are ROHS-Compliant Stepper Motors and carry CE Certificate marks. For quality assurance, an ISO9001 Stepper Motors manufacturer like ACT MOTOR demonstrates a commitment to consistent production processes.

Application-Specific Considerations

Your application dictates specific needs. Here’s how to tailor your selection:

- Medical Equipment Hybrid Stepper Motor: For stepper motors for syringe pumps or diagnostic equipment, prioritize smooth motion, low noise, and certified cleanliness. A Brake Stepper Motors option might be necessary for safety holding.

- Automated Packaging Lines: High-torque stepper motors for automated packaging lines need durability and the ability to handle variable loads. An Intelligent Load-Adaptive Hybrid Stepper Motor system can automatically adjust current to save energy and reduce heat.

- Textile Machinery: Stepper motors for textile machinery often run for long hours in humid conditions. Look for robust construction and high-temperature insulation classes.

- Compact Automation: When space is premium, consider integrated stepper motors or 8HS Hybrid Stepper Motors/NEMA8 Hybrid Stepper Motors which combine a small footprint with sufficient power for light-duty tasks.

The Manufacturer Factor: Why ACT MOTOR Stands Out

Choosing a supplier is as important as choosing the product. Changzhou ACT Motor Co., Ltd. exemplifies the qualities of a reliable partner in the motion control space. As a high-tech enterprise with over 70,000 square meters of integrated production facilities, ACT MOTOR controls the entire manufacturing process, ensuring quality from raw material to finished Hybrid Stepper Motor.

Their product portfolio is vast, covering not just standard hybrid motors but also specialized variants like Lead Screw Stepper Motors, Geared Stepper Motors, and complete closed-loop stepper motors systems. This breadth allows them to provide tailored solutions rather than just off-the-shelf components.

A global service network, including a branch in Bremen, Germany, ensures responsive technical support and local inventory for international customers. Their commitment to certification—holding ISO9001, CE, and RoHS certificates—provides the assurance that their motors meet stringent international standards for quality and environmental safety.

For your next project requiring a stepper motor with encoder, consider reaching out to their team for a consultation. They can help match their 8HS Hybrid Stepper Motors, NEMA8 Hybrid Stepper Motors, or larger frame motors with the right encoder and driver to create an optimal motion solution.

Final Checklist Before You Purchase

- Have you clearly defined your torque, speed, and precision requirements?

- Is the encoder resolution suitable for your positioning needs?

- Does the chosen driver fully support the closed-loop function and your preferred network protocol?

- Are the motor's environmental ratings (IP, temperature) adequate for your operating conditions?

- Has the manufacturer provided relevant compliance certificates (CE, RoHS, ISO9001)?

- Does the supplier offer technical support and reliable after-sales service?

- Have you considered total cost of ownership, including energy efficiency and potential downtime?

Pro Tip: Don't just buy a component; invest in a solution. Partnering with a technically proficient manufacturer like ACT MOTOR can save significant time and cost during integration and throughout the machine's lifecycle. Visit www.act-motor.com to explore their range of Hybrid Stepper Motor solutions or contact their engineering team at market@act-motor.com / Phone/WhatsApp: +86 13961261588 for personalized guidance.

The landscape of industrial motion control is rapidly embracing intelligence and connectivity. By carefully selecting a stepper motor with encoder based on this guide, you are not just solving a motion problem—you are future-proofing your equipment, enhancing its capabilities, and building a foundation for smarter, more resilient automation.